You don’t have to look far to find exciting architecture projects in the world of wine. From Frank Ghery’s famous - flamboyant - Marqués De Riscal winery in Rioja Alavesa to the UFO-like Le Dôme winery in Bordeaux designed by Foster & Partners, great architects really like getting their teeth into cellar design.

One of the latest major projects to land is the new winery from Champagne legends Krug. Simply named ‘Joseph 2.0’ after Krug founder Joseph Krug, whose original cellar in Reims has been the house’s key winemaking facility since 1843, this new ‘vinification hub’ in the village of Ambonnay opened its doors last month ahead of the 2024 harvest.

Joseph 2.0: the new Krug winery

The winery was seven years in the making - from conception, to design and build - which coincidentally is the same amount of time each Krug Grande Cuvée takes to make.

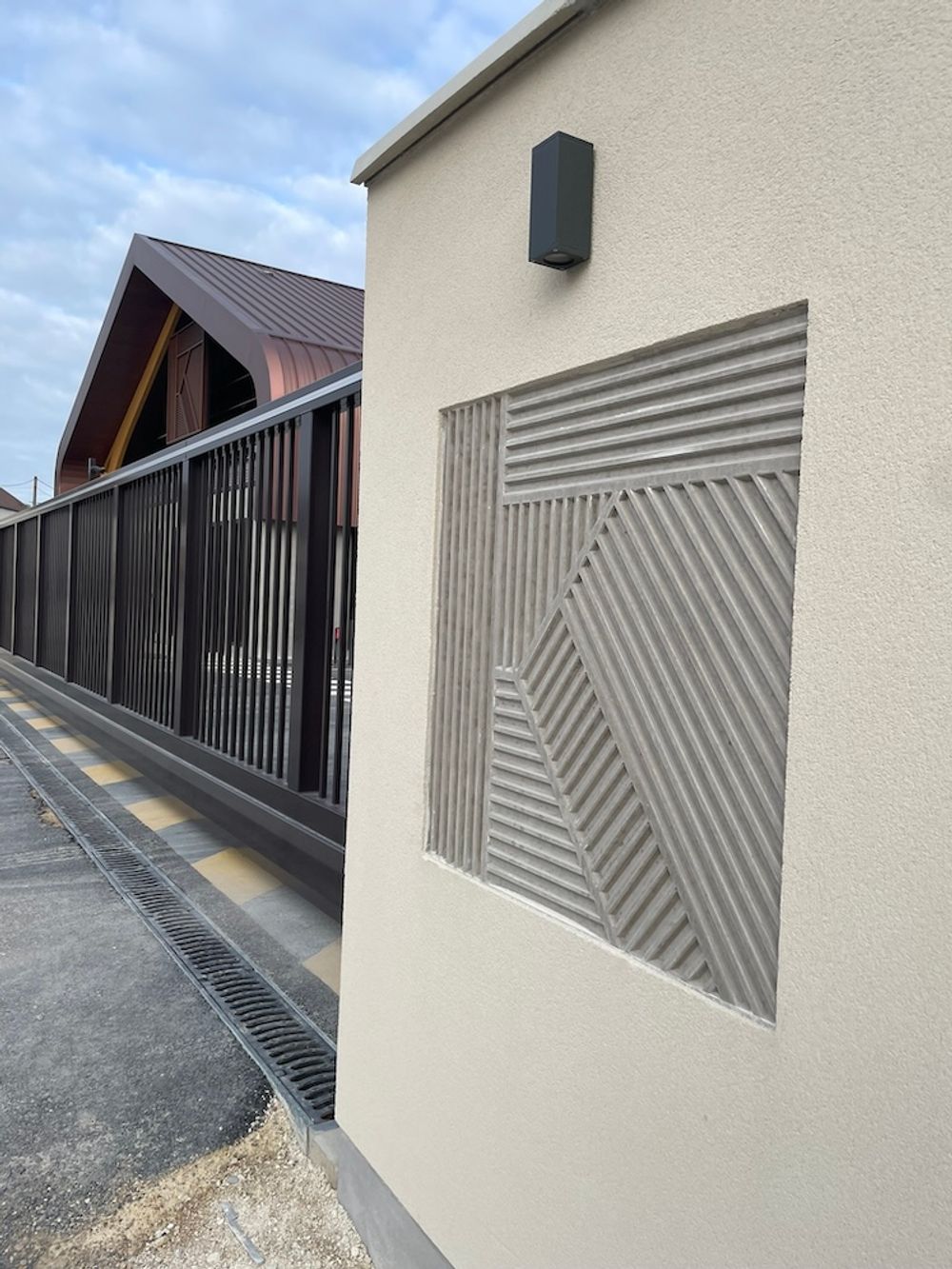

Situated adjacent to Krug’s Ambonnay vineyard in the commune of the same name, this tiny, pretty village lies 30 km to the south east of Reims and, given the size and ambition of the new winery, you’d think that it would stick out on the landscape.

You’d be wrong. Such is the design of the site that you barely notice it until you are upon it, as it rises from the ground to show off its two symmetrical arches wrapped in bronze metal. Joining the arches are a series of offices and a tasting room, with a courtyard to the front and a walled garden to the rear, next to the existing vineyard.

Paris-based architects AW² designed and managed the project, led by Stéphanie Ledoux. Here’s how they describe the winery: “The project is composed of two large naves that host the new cellars below and whose curved form and copper-coloured roofs blend the complex into the site situated on the periphery of the town of Ambonnay and the vineyards beyond.”

In total the site is 9,400 m² and comprises four barrel rooms and two large cellars below full of stainless steel tanks. Gravity does a lot of the heavy lifting here, and it’s clear that a lot of input from winemakers went into the design and function of the building.

Many wineries designed by sharp-eyed architects can end up as beautiful, eye-catching buildings, but are often functionally floored as the architects/owners/those with the purse strings do not understand the nature of the winemaking process and how this can be optimised by good design. This building is not like that at all.

Krug’s chef de caves Julie Cavil had a hands-on role throughout the process and it tells. When we are looking around the winery with her she’s less interested in the materials, curves and colour palettes and more keen to talk about the winemaking innovations which have gone into the build. Things which make her and her team’s life easier.

She’s particularly excited about a new barrel rack that’s been designed for the winery. Each rack holds two barrels at different heights and tessellates into the next rack. Every barrel sits on four spinning wheels which makes emptying (racking) the barrels after fermentation easy and alleviates the physical process of lifting heavy barrels by hand.

There are 5000 barrels housed in the new winery

With 5,000 barrels in the new winery this will cut out a lot of heavy lifting for the winery team. It’s worth noting that while all Krug wines are fermented in small 220-litre oak barrels (old, neutral oak), the wine does not mature in oak, it’s racked (via gravity) soon after fermentation and settling into the stainless steel tanks below.

Even though the winery is brand spanking new, the centuries-old Krug winemaking process remains the same. The key to each wine is the number of blending components which come together to make it what it is, hence the ridiculous number of micro-cuvées in barrel. Blending decisions are made on a vintage-by-vintage and wine-by-wine basis, with lots of base wine and reserve wine tasting along the way.

During the visit we experienced a snapshot of this tasting regime first hand. Over the course of an hour – and sitting in the new tasting room overlooking the vines – we tasted a dozen or so base wines from the 2023 vintage, which will create the heart of a future Grande Cuvée edition (the 179th). It was hard work; these are high acid wines which are difficult to pin down, let alone envisage how they would work in a blend alongside older reserve wines which then go through a secondary fermentation before ageing for seven years in bottle.

It was an eye-opening – and palate testing – experience. Julie Cavil clearly relishes this part of the process, and fully trusts each person and each palate on the tasting panel who come together to put the blends together. “The aim is to get close to the truth through tastings and teamwork,” she says.

Tasting base wines from the 2023 vintage in the new tasting room overlooking the vines

The proof of the pudding comes this autumn

The moving of winemaking out of the Krug cellar in Reims to the new site in Ambonnay will be fully tested this autumn when the 2024 harvest begins, and Julie and her team cannot wait. New technology – including a bespoke barrel washing machine designed in Italy – will enable the winemaking team to be more efficient and even more precise in its cellar work, and spend less time moving things around (the bane of every winemaker). There have been numerous small tweaks to the process as a result of the new winery design.

We’ve seen this use of marginal gains before, notably in British cycling, and Krug – with its thousands of barrel fermentations – seems well placed to benefit. If they can make tiny adjustments and improvements along the way in a process with this number of moving parts, who knows where it will take them?

I ask Julie if this precision and attention to detail runs the risk of being too perfect, and propose that sometimes great wines are created because of the ‘cracks’ in the process. Would she, theoretically, like to attempt a harvest where the parcels of grapes are fermented together just to see what the result might be?

“Do you think we are bored?,” she jokes, but can understand where I’m coming from. A lot of change happens behind the scenes and the Krug winemaking team is constantly experimenting, but so far the original formula has yet to change much. “And not just because Joseph Krug used to do it like that,” she adds.

When the new Joseph 2.0 cellar gets fully tested during the 2024 harvest it will be interesting to see how that affects future Krug wines, in the way they are made and in the way that they taste. “The new building is about technology,” says Cavil, “it's about pushing technology because it doesn't affect the taste of the wine, [rather] it affects the efficiency of the process.”

It will be fascinating to be a fly on this wall this autumn when the harvest kicks off and the grapes come rolling in. Until then there are a few finishing touches to be put to the new winery but, judging by the way it looks and feels already, this beautiful compromise between form and function should yield superb results…. we’ll just have to wait seven years to find out.

Tasting the two new Krug cuvées

Krug Grande Cuvée 172nd Edition

Built around the 2016 vintage, and comprising 146 different wines across 11 years, this is a lithe and generous expression of Krug. It has fresh peach on the nose backed up by citrus fruit, bread and Marmite. On the palate there’s lovely balance, with initial freshness giving way to richness and poise. Stone fruit, pineapple, buttered potatoes and caramel all come to the fore as the generous mousse fills the mouth. Elegant and refined but so very approachable.

Krug Rosé 28th Edition

‘Re-created’ around base wines from 2016, there are 32 different wines in the 28th Edition of Krug’s rosé, the oldest going back to 2010. Reserve wines make up 38% of the blend, and come from five different years. The starting point for all Krug rosés is structured white base wines which can handle the addition of red wine. This is light-footed and svelte with a dash of berry character on the nose and a hint of savoury oxidative notes. There’s lovely ripe stone fruit here too and a delicate waxiness. It’s lean with a bone dry finish and a bite of tannin and spice. A lovely textual wine.